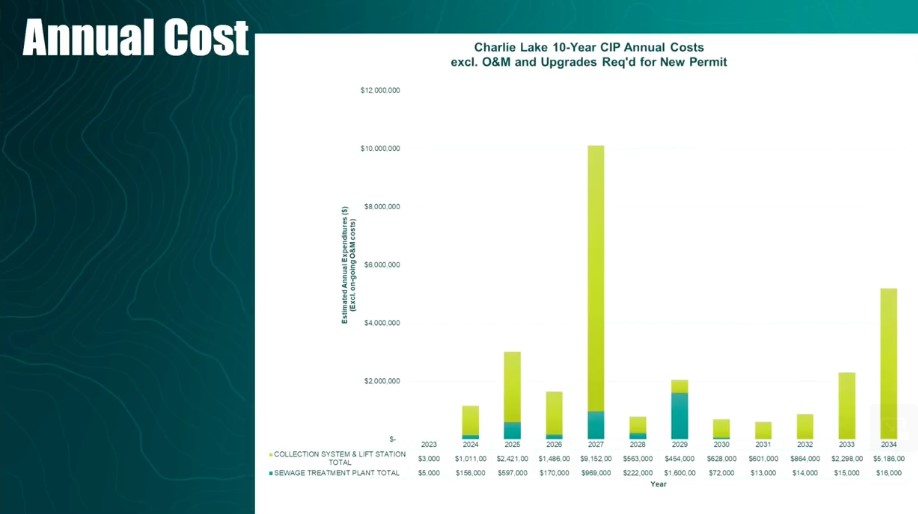

Major repairs and updates to the Charlie Lake Sewer System are needed, according to a Capital Plan report McElhanney Ltd. provided to the Electoral Area Directors Committee at its October 19 meeting. The recommended repairs are expected to take place in stages over the next decade, at a cost of $24.67 million.

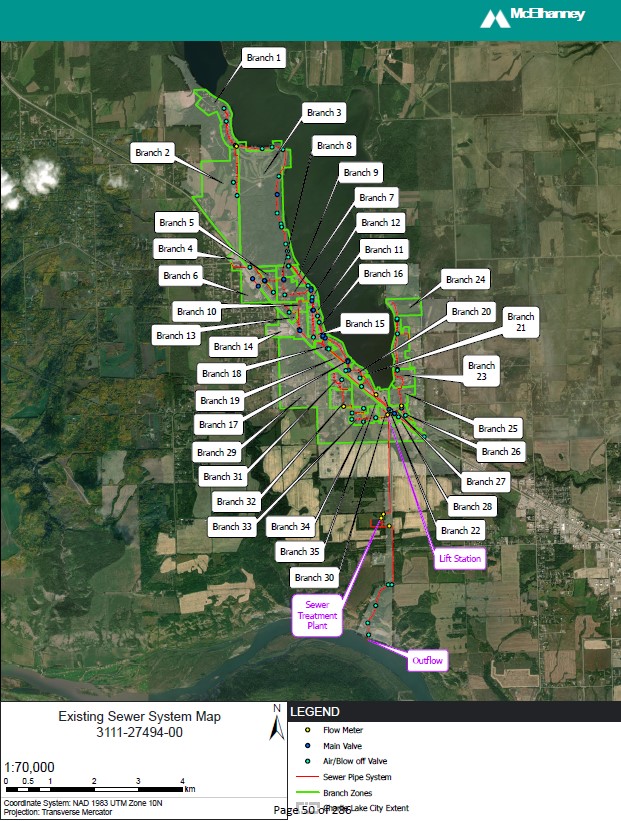

The Charlie Lake Sewer System is a STEP system, which means that each residence or industrial lot has a septic tank and an effluent pump. The solid wastes are stored in the septic tank, and the effluent flows into the main collection system. The effluent is transported via pipes to the lift station on the 273 Road, and then into wet wells before going through the sewage treatment plant and then into aerated lagoons, before eventually being discharged into the Peace River.

Since it’s construction in the 1990s, the system has been gradually expanded as new homes were added, and now serves 434 of the 573 lots in Charlie Lake.

McElhanney was tasked with developing a capital improvement plan for the Charlie Lake sewer system for 2023-2034. To develop the plan, McElhanney reviewed a variety of existing data sources for the sewer system to evaluate the current function of system, identify deficiencies, and recommend priorities for improvement and expansion. This included the creation of a new Capacity Tool, which is a more efficient, spatially oriented software, developed specifically for the Charlie Lake sewer system.

Over the past few years, the system has developed several issues, McElhanney’s engineer, Abbi Kau explained. Among the issues are complaints of smells coming from the system, and the possibility of leaks from the effluent pipes. Because of the odors, some of the blow-off valves in the system have been closed, resulting in an increased concentration of H2S gases. As the gases can’t escape, they remain in the pipes until they reach the lift station.

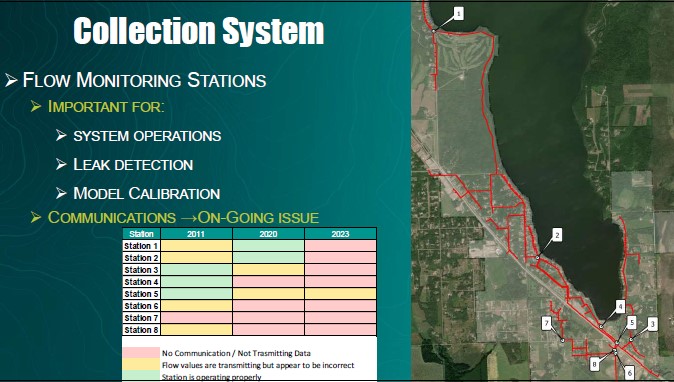

“This may have contributed to some of the seized gate valves in the system,” Kau said. “Most of the flow monitoring stations are not working, due to communication errors. This has been an ongoing situation since the monitoring stations were installed, and it has gotten worse.”

Evaluating communications and the flow monitoring stations to make sure the data is being transmitted is important, as it helps operators identify leaks in the system – with the potential for gases being built up in the effluent pipes due to the closed blow-off valves, this is a very real possibility. Checking the flows and pinpointing any leaks is difficult, if not impossible when the flow monitoring stations are not functioning. The eight flow monitoring stations measure the flow of effluent through the system to the lift station.

“If you only check the flows at the lift station, the leak could be anywhere in the system,” said Kau. “Flow monitoring stations can help pinpoint leaks.”

In 2020, only two of the monitoring stations were operating correctly. Analysis of the stations in 2023 shows that seven of the stations are not transmitting flow data at all, and the one that is transmitting, appears to be doing so incorrectly.

The Lift Station also has issues, Kau said. While the capacity is good, having had a second wet well added in 2005, there are concerns about corrosion, pump control and the SCADA system. In 2015, new valves, pumps and ultrasonic level sensors were installed.

Since 2015, three leaks have been detected. In repairing the leaks, it became apparent that not all the infrastructure is identified in the available drawings. A field evaluation of the existing system is necessary so that specific projects for rehabilitation or replacement of infrastructure around the lift station can be recommended.

“There is a quite a bit of capacity with the two wet wells, so that’s not a concern,” said Kau. “There are a lot of questions about what is connected, where the flow is going and what valves are needed.”

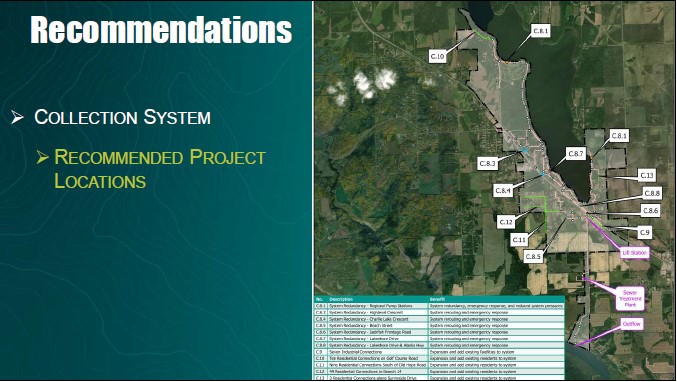

“Right now, there are several sections where, if there was a line break, there would be a lot of homes without service,” she said. “The system wouldn’t be able to get the flows to the lift station, which would result in septic tank back-ups.”

“(The system) needs to allow redirection of flows around potential line breaks, so that homes can still use their septic tanks.”

The report recommends that in 2024, the system be cleaned up, remove unused infrastructure, and make sure that everything is working.

The final piece of the sewer system, is the Sewage Treatment Plant. From its lagoons, the treated wastewater discharges into the Peace River, which is planned to be flooded in the fall of 2023 for the Site C Dam. Changing the discharge water body from a river to a reservoir will impact the discharge regulations and requirements, and the report says that discussions are underway to determine the new requirements.

Other concerns noted during the analysis of the Treatment Plant include a lack of data for trucked waste, a lack of process data to allow for process optimization, sludge accumulation in the anaerobic cells, freezing, and values that differ from the design parameters for the system.

Additional sampling and monitoring would provide data about what’s coming into the facility through trucked waste and industrial discharges, according to McElhanney engineer Karen Sutherland. More sampling within the treatment process will help operators “to understand how the bacteria are working and what stage they are at in their various cycles, particularly as it relates to the nitrogen cycle and ammonia removal.”

“Most of the sampling programs are to be done next year,” Sutherland said.

The recommended capital improvements need to ensure proactive system maintenance and consider future growth and improvement of the system. The population in the Charlie Lake area is expected to increase in the next ten years, and it is vital to provide for both current and future needs, while also correcting the issues that exist today.

Have an insight or additional info regarding this article? Feel free to drop a comment!